Customised preformed cemented carbide blanks - manufactured from around 30 different types of cemented carbide.

In our Swiss production facility, we manufacture blanks according to your specific requirements, which are sintered blank and then delivered directly to you.

Our experienced team is on hand to advise you on the optimum carbide grade for your application. Simply contact us - we are here for you!

Our strengths

- In-house development of carbide grades (customised to your needs)

- Precise shaping of the green parts (saves costs during further processing)

- Optimised sinter-HIP process (hot isostatic pressing)

- Short delivery times (increase your competitiveness)

A list of grades with the most important properties of our cemented carbides as well as information on the production of cemented carbide and its applications can be found in the WMC brochure.

WMC Broschüre

#HM_Sortenübersicht

Overview of carbide grades

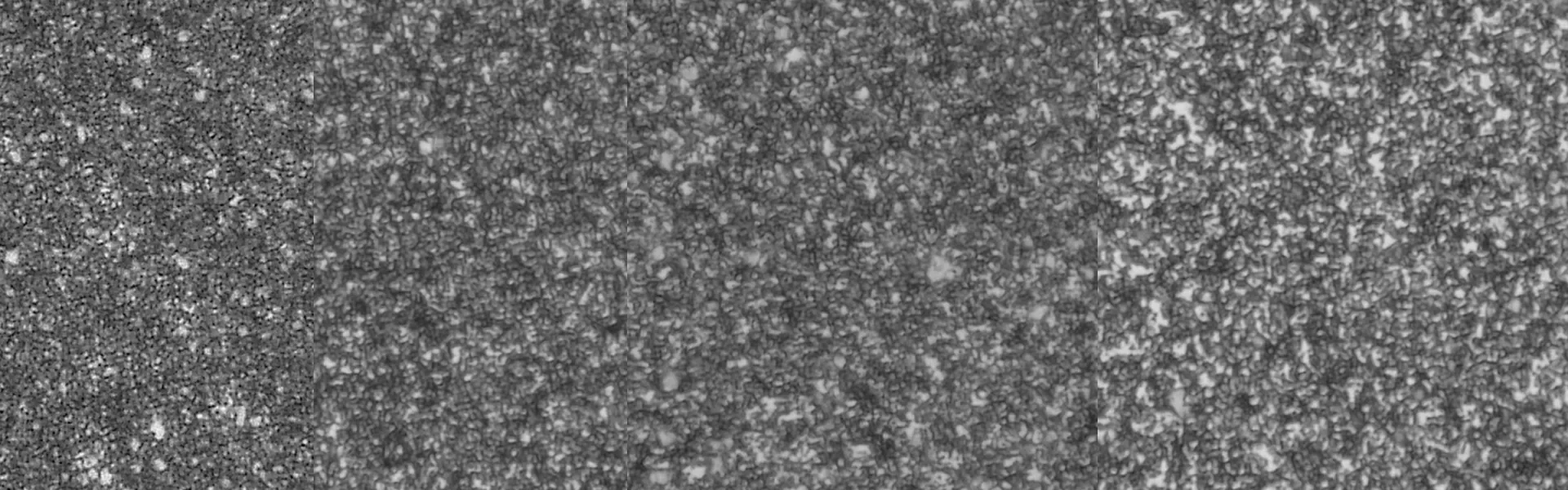

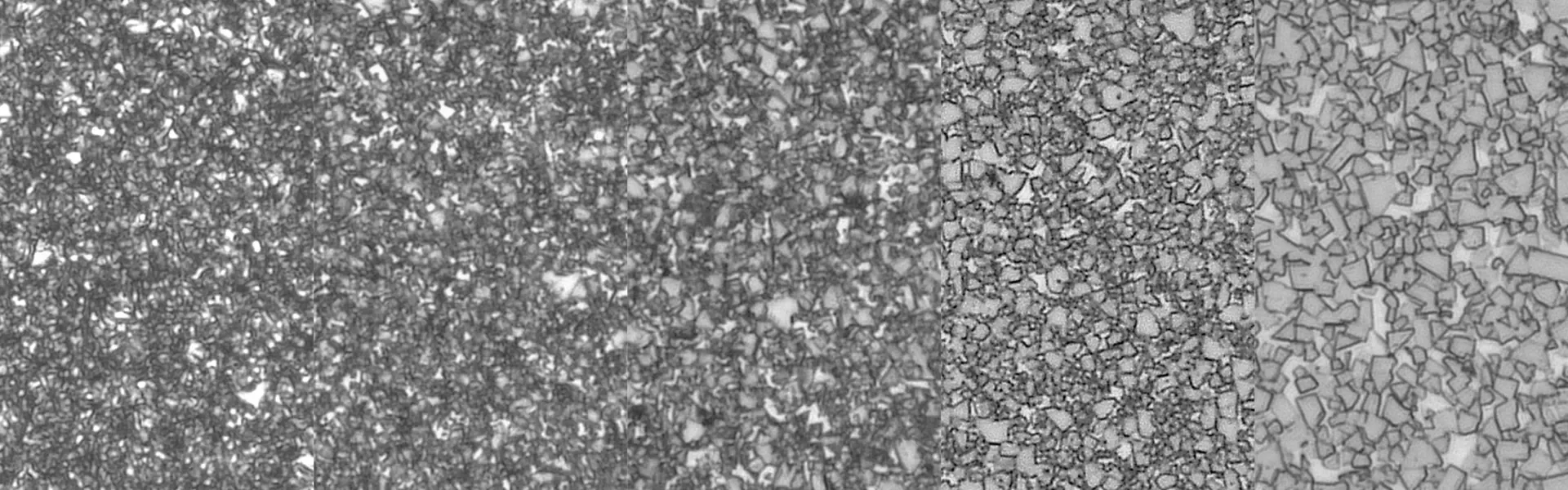

We have a wide range of carbide grades, suitable for every application. In addition to the standard grades of WC ultra-fine grain, fine grain, medium grain and coarse grain with cobalt or nickel as a binder, we also produce special grades for well-known customers as part of projects.

Below you will find an overview of our grades. Our special grades include our low-stress and corrosion-resistant erosion grades, which are ideal for the manufacture of pressing, stamping, embossing and forming tools using wire and die-sinking EDM, as well as our corrosion-resistant, nickel-bonded carbide grades for applications in the chemical industry, plastics production, ore mining and industrial food processing.

You can find more details on the individual grades in the corresponding data sheets, which you can find under Downloads.

WC ultra-fine grain

Very high hardness and wear resistance, used as wear protection and milling tools

UM20 HIP, UM30 HIP, UM40 HIP

WC fine grain

SM20 HIP, SM30 HIP, SM30E HIP, SM40 HIP, SM50 HIP

WC medium grain

V20 HIP, V30 HIP, V40 HIP, V45E HIP, V50 HIP, V50E HIP, V50T HIP, V60 HIP, V70 HIP

WC coarse grain

High crack resistance and impact strength, well suited for forming tools

B50 HIP, B70 HIP

Corrosion resistant grades

Resistant to most acids, aqueous salt solutions and all organic substances and solvents, used in slide rings, pumps, grinding systems, injection nozzles and in the food industry

TN08SM HIP, TN08F HIP, TN10 HIP, TN10N HIP, TN12E HIP

#HM_Innovation

Innovations in cemented carbide

As a specialised niche supplier, we not only offer you the usual standard grades, but also carbide grades with customised properties that are precisely tailored to your requirements. We can produce special alloys for you from a batch of just 50 kg to meet your individual requirements.

Our innovation programme includes in particular:

Corrosion resistant grades (TN)

Hard metals bonded with nickel and mixed with chromium for use in the chemical industry, resistant to most acids, aqueous salt solutions and all organic substances and solvents. Used in slide rings, pumps, grinding systems, injection nozzles and in the food industry. The following grades are available:

| HM grade | Fineness | Percentage nickel (Ni) | Properties |

|---|---|---|---|

| TN08SM HIP | ultra-fine grain | 8.5% | hard and wear-resistant |

| TN10 HIP | medium grain | 10% | standard grades |

| TN10N | medium grain | 10% | non-magnetisable |

| TN12E HIP | medium grain | 12% | erosion grade, impact-resistant and crack-resistant, solderable |

Coarse grain grades (B)

We offer two grades with 15% and 25% cobalt binder, which have high crack resistance and impact strength. These are mainly used as forming tools.

| HM grade | Fineness | Percentage cobalt (Co) | Properties |

|---|---|---|---|

| B50 HIP | coarse grain | 15% | impact-resistant and crack-resistant |

| B70 HIP | coarse grain | 25% | impact-resistant and crack-resistant |

Ultra-fine grain grades (UM)

Based on a WC grain size of 0.4 micrometres, we have developed three correspondingly hard and wear-resistant carbide grades that are used in wear protection and as milling tools:

- UM20 HIP, ultra-fine grain with 7% cobalt, for throwing blades and cladding as well as milling tools for machining abrasive materials and non-ferrous metals

- UM30 HIP, ultra-fine grain with 9% cobalt, medium grade

- UM40 HIP, ultra-fine grain with 11% cobalt, for cutting and milling tools for machining tough, high-alloy steels and titanium.

| HM grade | Fineness | Percentage cobalt (Co) | Properties |

|---|---|---|---|

| UM20 HIP | ultra-fine grain | 7% | hard and wear-resistant |

| UM30 HIP | ultra-fine grain | 9% | hard and wear-resistant |

| UM40 HIP | ultra-fine grain | 11% | hard and wear-resistant |

Erosion grades (E)

These specially developed carbide grades are ideal for the manufacture of tools by wire and die-sinking EDM, in particular pressing and punching tools, such as those used in electrical sheet metal processing. Thanks to special additives, they are corrosion-resistant against pitting in the EDM bath and feature stress reduction to prevent cracks during machining and in use. We currently offer four eroding grades:

- SM30E HIP, ultra-fine grain with 10% cobalt, our hardest erosion grade, used for abrasive and thin sheets

- V45E HIP, medium grain with 12% cobalt, our standard grade

- V50E HIP, wide medium grain with 15% cobalt, extremely crack-resistant and low-stress, used for thick sheets and tough steels

- TN12E HIP, wide medium grain with 12% nickel, corrosion-resistant to chemical substances, very impact-resistant and crack-resistant, solderable

| HM grade | Fineness | Percentage cobalt (Co) / nickel (Ni) | Properties |

|---|---|---|---|

| SM30E HIP | ultra-fine grain | 10% Co | hardest erosion grade |

| V45E HIP | medium grain | 12% Co | standard erosion grade |

| V50E HIP | wide medium grain | 15% Co | extremely crack-resistant and low-stress |

| TN12E HIP | wide medium grain | 12% Ni | impact-resistant and crack-resistant, solderable |

Temperature ressistant grades (T)

V50T HIP is a medium grain with 15% cobalt. By adding tantalum carbide, we increase the temperature resistance and reduce the tendency to weld. This grade is mainly used for wire guides and wire moulds.

| HM grade | Fineness | Percentage cobalt (Co) | Properties |

|---|---|---|---|

| V50T HIP | medium grain | 15% | temperature resistant |

Cost optimisation of cemented carbide rods

In cooperation with a renowned partner company in China, we produce cemented carbide round rods and rectangular rods in lengths of 330 mm as well as fixed lengths at significantly lower costs. Our partner relies on our proven WMC carbide grades SM30 HIP and UM40 HIP as well as our WMC sintering processes. This enables us to offer you Swiss quality standards at attractive prices. Our partner is certified to ISO 9001 and ISO 14001, and is also working on aviation certification to EN 9100.

We manufacture all other carbide products exclusively in our factory in Switzerland.

#HM_Rohstoffe

Our raw materials

#HM_Rohstoffe

Our raw materials come exclusively from conflict-free sources in accordance with the Dodd-Frank Act. We rely on virgin raw materials, which are obtained from tungsten oxide through complete chemical conversion. In contrast, we do not use low-cost raw materials that are merely mechanically processed from recycled hard metal scrap (zinc process). Such materials can have impurities due to incorrect grain sizes, foreign metals or coatings, which can have a negative impact on the metallurgy and therefore on the quality of the carbide tools produced. Further details can be found in our research report, which we produced together with Hartmetall Estech AG.

all text translated from German to English with deepl.com